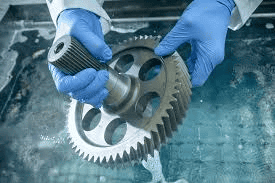

Industrial manufacturing is often a dirty process, producing pollutants and gathering dirt and grime that can accumulate inside essential machinery components. Keeping components clean of contaminants that can rust, corrode or damage them makes good business sense, reducing downtime and the cost of replacements.

So, what are the different methods available for ensuring these vital parts stay efficient?

Hand Washing – This is the cheapest method but is time-consuming in terms of labour and prone to human error. Some of the parts might not receive the thorough clean they need to achieve maximum efficiency.

Degreasing – This method uses solvents to wipe, brush or spray away grease, oil or other contaminants that have accumulated on components. This is a relatively cheap method to set up and works well for electrical parts and metals but solvents pose a fire risk and adequate ventilation is also a consideration.

Ultrasonic Cleaning – This is a process that uses the cavitation of bubbles to remove contamination. The bubbles are created using high frequency sound waves. The liquid agitation provides a strong cleaning force that can reach inside holes, fissures and tiny crevices in components. Ultrasonic cleaning can remove bacteria, fungi, grease, oil, rust, limescale and fingerprints. It is widely used as an effective cleaning method in aerospace, pharmaceutical and automotive industries. Find out more about Anilox Cleaning Equipment by visiting a site like Caresonic, suppliers of Anilox Cleaning Equipment.

Parts Washers – These are large cabinet-style machines that can eliminate contaminants such as ink, paint, oil and rust. They are ideal for bulk loads of parts, large or small. They can use solvents or be aqueous based and use mechanical energy and heat to clean. These machines are highly versatile and offer efficiency with short cleaning cycles.

Spray Washing – This method involves aiming a high pressure jet at a specific area to remove contaminants. For harder to remove stains, a specific temperature and pressure may need to be applied and this method is not ideal for parts with holes, fissures or cracks that are difficult to clean.

When choosing a cleaning method, it is important to pick the right process for the material and factor in the fact that you might need to use different methods and cleaning agents depending on which contaminant you are removing. Cleaning methods should also be able to offer efficiency whilst causing no damage to the components in question.